According to the latest research, the automotive industry is estimated for a significant shift. By 2025, the value of electronic components in high-end vehicles is projected to surpass $6000, driven by the increasing sophistication of vehicle features. This trend is expected to accelerate if the EU successfully bans the sale of internal combustion engine vehicles by 2035, leading to an even higher proportion of electronic components in electric vehicles.

Despite the technological advancements in electric vehicles, the demand for robust and reliable automotive electronic components remains paramount. The failure of electronic control systems during driving can pose serious safety risks to passengers.

A critical component in the vehicle’s electrical system is the reverse polarity protection circuit. This circuit safeguards the battery and other sensitive electronic components from damage caused by reverse current, which can occur due to human error, external forces, or environmental factors. The ISO-16750-2 4.7 standard outlines specific safety requirements for transient reverse voltage testing.

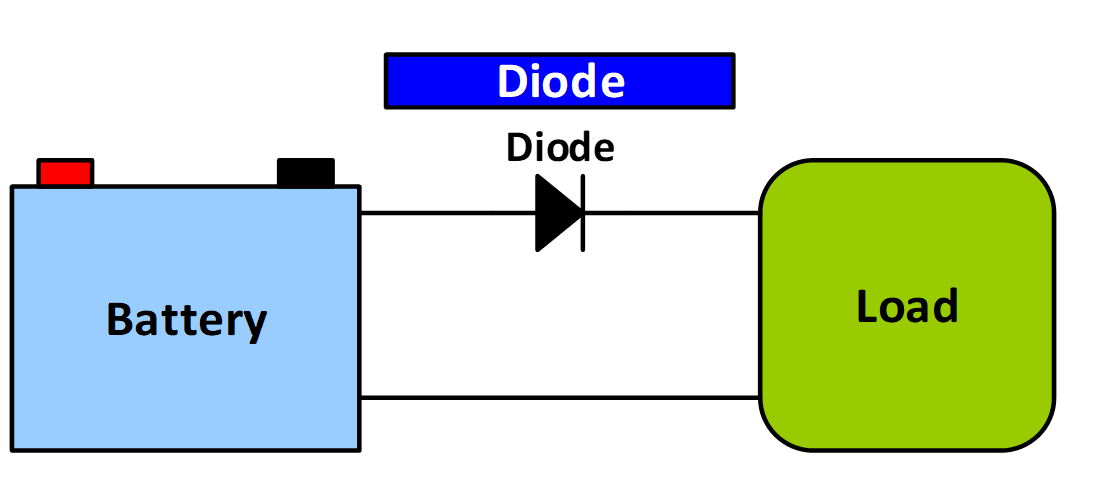

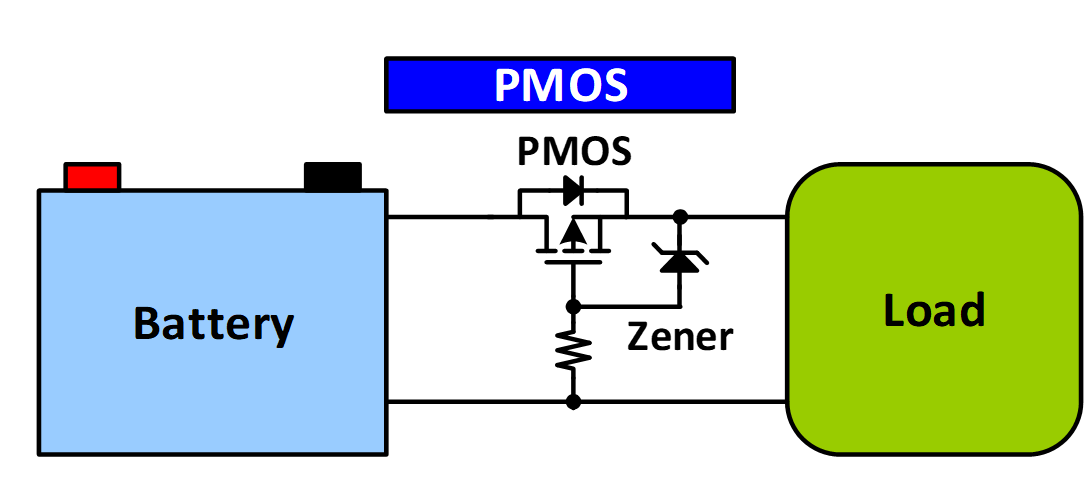

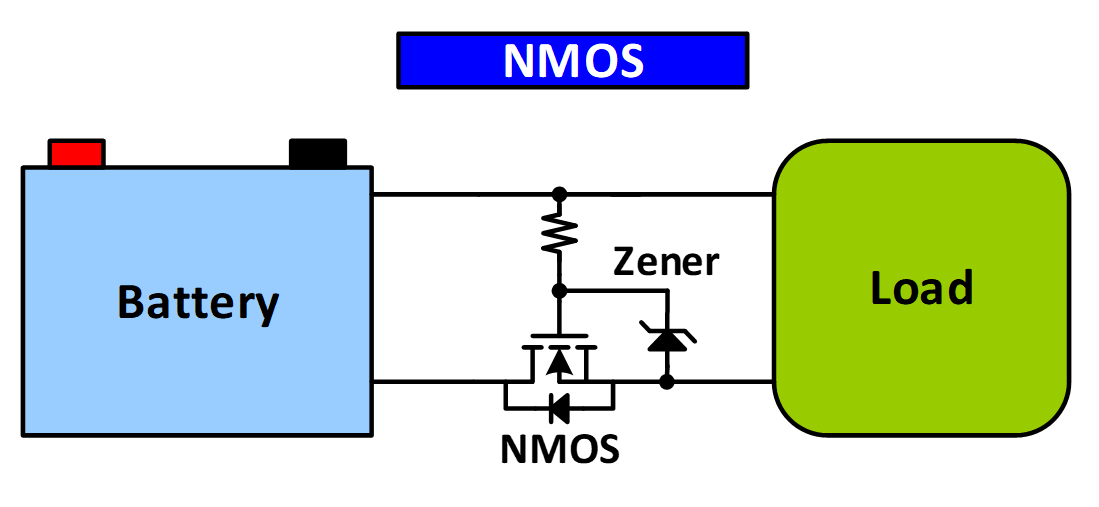

One common design for reverse polarity protection circuits involves a series diode. While this method is simple, it results in significant power dissipation due to the voltage drop across the diode. For higher-power applications, MOSFETs are used to reduce power losses. Figures 2 and 3 illustrate the use of P-channel and N-channel MOSFETs, respectively. Although MOSFETs offer improved efficiency, they typically require more space and increase overall design costs.

When a battery applies reverse polarity, the diode becomes reverse biased, preventing current flow. Similarly, in MOSFET-based circuits, a reverse input voltage causes the MOSFET channel to close, effectively blocking the current.

Beyond reverse voltage, numerous devices, motors, relays, and wiring harnesses within vehicles can generate voltage spikes of several hundred volts due to the inherent inductance, stored energy will be applied to the rest of the system.

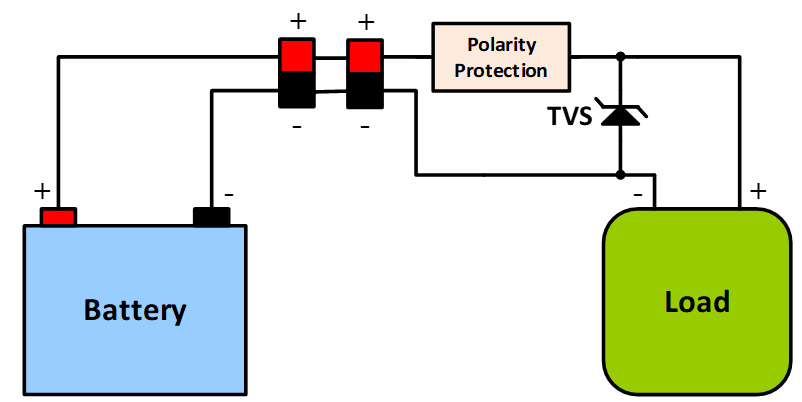

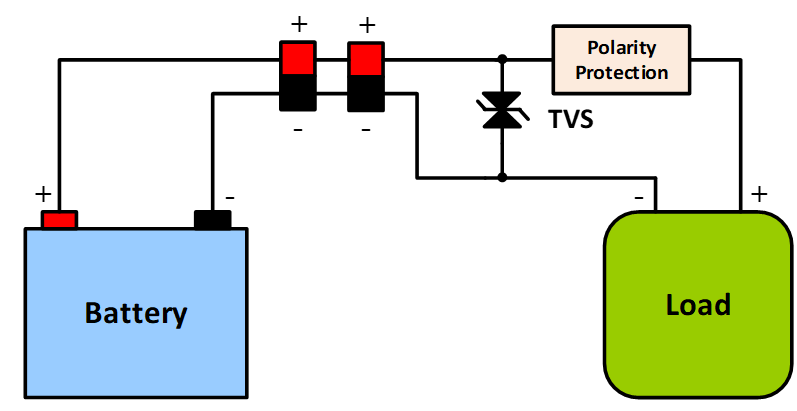

Additionally, static electricity often occurs in vehicles, and electrostatic transient voltage can reach thousands of volts. Since these transient voltages exceed the transient voltage tolerance of diodes, MOSFETs, and the system, TVS diodes are used in the protection circuit design to prevent these devices from being damaged by transient voltages. According to the relative position of the reverse polarity protection device, as shown in the figure, unidirectional or bidirectional TVS are used for negative polarity protection.

In automotive systems, having both TVS diodes and reverse polarity protection provides the system with protection against transient voltage and damage caused by incorrect battery installation. It also meets the safety standards for automotive-specific testing.

Taiwan Semiconductor’s automotive TVS devices fully comply with the AEC-Q101 standard are PPAP able and meet the specific automotive testing standards ISO 7637-2 (1-3b), ISO 650, and ISO 16750-2. Additionally, Taiwan Semiconductor can provide customers with AEC-Q101 qualified diodes, MOSFETs, and Zener diodes for protection device applications.

Products

Read more articles

- The Role of MOSFETs in Anti-lock Braking Systems (ABS)

- Beyond Braking: Advanced Driver Assistance Systems (ADAS) for a Safer Driving Experience

- Battery management system (BMS): Protecting and Managing Your Electric Vehicle

- Advanced LED Solutions for Enhanced Vehicle Visibility

- Power Components for On-Board Chargers (OBC): A Comprehensive Overview

- MOSFETs and Diodes: Key Components in Reverse Polarity Protection

- Sensor Fusion for Supplementary Restraint Systems (SRS)